We wanted to take a closer look at the grain storage industry and the latest innovations that are streamlining construction and boosting efficiency. Who better to share insights than Cory Thrush, project manager at LoweCon, LLC., and seasoned contractor with 17 years of experience installing grain bin systems like the GSI EVO 2X? Cory’s expertise in building durable and efficient grain storage solutions offers a unique perspective on how the EVO 2X grain bin sets a new standard for installation and long-term performance. Let’s hear from Cory about the standout features of the EVO 2X and why it’s a game-changer in the field.

Why is engineering efficiency critical when constructing large-scale grain storage systems?

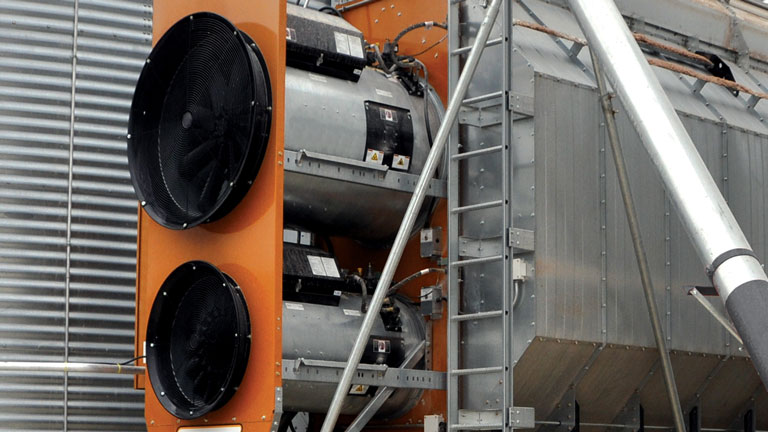

Engineering efficiency is crucial when constructing large-scale grain storage systems because it directly impacts installation efficiency, labor intensity and overall project success. The design of the EVO 2X grain bin helps streamline the construction process, reduce the complexity of installation and minimize errors.

Constructing a bin of this size without requiring more time than a traditional bin system is a testament to GSI engineering. This helps contractors complete projects on time and move on to the next job, which is important when building high-capacity grain storage.

How does constructing the EVO 2X grain bin compare to other systems you've built?

Constructing the EVO 2X grain bin system has several advantages. The double-length sidewall sheets are twice as long as standard sheets, reducing the number of vertical seam connection points to half that of a traditional grain bin. This lessens the number of bolts we have to tighten and allows for the use of lighter gauge steel for the sheets. While handling larger sheets initially posed a challenge, we developed efficient methods to move them, minimizing physical strain on our crew.

The EVO 2X system sheets' interlacing design is also a standout feature. This design eliminates the need for overlapping sheets, reducing the risk of leaks and moisture intrusion and improving the durability and reliability of the finished bin.

As a bin builder, I value the GSI bins' modular design and pre-punched panels. These bins are engineered to align a panel perfectly with pre-punched holes, making installation easier and eliminating the need for on-the-job modifications.

What benefits do you see for contractors when installing this system compared to others?

One key benefit for contractors when installing the EVO 2X system is that it doesn’t require learning an entirely new skill set. While the bin's engineering has been improved, the fundamental process of building the bin remains familiar. This means contractors like myself can transition smoothly without extensive retraining.

Additionally, the engineers were highly collaborative during the development process, seeking feedback and ensuring the manual provided clear instructions. This allowed for a smooth integration of the new features without adding unnecessary complexity.

How do the advantages of the EVO 2X grain bin system extend to the customer?

I can absolutely see that the improvements they've made to the bin benefit the farmer. First, the interlacing design of the sheets reduces the number of seams and bolts, minimizing potential leakage points. Fewer seams mean fewer places where leaks can occur, making the bin more reliable over the long term. This leads to fewer maintenance issues and less risk of product loss.

As a contractor, I’ve noticed that the improvements make the bin easier to seal up, reducing callbacks from customers due to leaks. Overall, the EVO 2X’s design increases durability and lowers maintenance needs, resulting in a more efficient, hassle-free grain storage solution for farmers.

How did GSI support you when learning to install the EVO 2X grain bin system?

GSI was very supportive during the transition to the EVO 2X grain bin system. It took us about a season to fully get comfortable with the new design, but GSI was always responsive and available when we needed help. They set up multiple video calls with their engineers to address any concerns or issues we encountered and were open to our feedback throughout the process. The engineers did a great job of providing clear guidance through the build manual, offering support and clarification until we felt confident in constructing the new system.

Learn more about the GSI EVO 2X grain bin system.

Are you looking to expand your commercial grain bin storage? Learn more about the advantages of the EVO 2X grain bin system and find a dealer near you.