On-farm storage is more than just a convenience for grain producers. It’s a vital asset for protecting grain quality, providing flexibility in commodity markets and allowing growers to maximize revenue potential by keeping grain on-site.

“Grain prices are rarely lower than during harvest and seldom higher than just before harvest,” said Mat Tallman, Senior Product Manager at GSI. “Investing in on-farm storage allows producers to hold their crop until the market conditions align with their goals, giving them a significant advantage.”

While a grain bin’s core purpose remains the same, no two farms are alike. Operational goals, grain types and required storage space vary significantly from producer to producer. That’s where customization comes in. Tailoring a grain bin system to specific needs can unlock additional efficiencies and benefits, setting your operation apart.

The Value of Grain Bin Customization and Flexibility

A one-size-fits-all approach doesn’t work for farming operations, and GSI understands that. Customizable grain bins and accessories enable growers to design a storage system that fits their unique needs while allowing room for future growth.

“No two farms are the same,” said Tallman. “Being able to tailor equipment to meet specific operational goals, pain points and long-term plans is critical. Our dealers work closely with producers to provide solutions, not just products.”

This adaptability allows growers to:

- Address unique operational needs by customizing systems for space, grain types or drying requirements.

- Plan for growth by upgrading or expanding storage without starting from scratch.

- Manage costs efficiently by adding advanced features over time as their operations evolve.

Additionally, GSI’s broad portfolio of products — from storage to material handling and conditioning systems — allows growers to create efficient grain management solutions that are best for their operations.

Grain Bin Customization Options That Work for You

GSI offers a wide range of customizable grain bin accessories designed to optimize storage, enhance safety and improve operational efficiency, including:

- Customizable flooring options: Cut-Lok floors prevent restrictions to airflow and provide an efficient and reliable solution for common crops such as corn and soybeans. Dura-Lok floors feature a unique locking system that reduces floor movement and supports extreme load conditions, making it ideal for large-scale grain storage. GSI also provides flooring with various perforation sizes to ensure optimal aeration for smaller grains such as canola or rice, preventing material loss and maintaining grain quality.

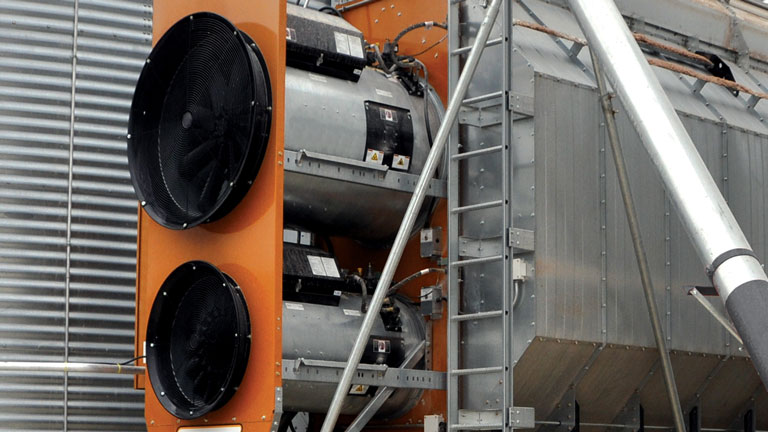

- Fans and aeration systems: Maintaining grain quality requires proper airflow, and GSI provides various solutions to meet different needs. Vane axial fans offer a cost-effective choice for standard applications, while centrifugal fans deliver high performance with greater airflow and pressure, making them ideal for larger or taller bins.

- Bin Sweeps: The Direct Gear Drive power sweeps feature a redesigned center well with fewer components for easier installation and durable steel roller bearings for smooth gate operation and long-lasting performance. The GSI paddle sweeps use flexible rubber paddles to move grain gently, protecting grain quality and minimizing damage.

- Stairs, ladders and platforms: Safety and accessibility are key considerations for any grain bin system. GSI addresses these needs by offering stairs that provide safer and easier bin access compared to ladders, as well as roof stairs and platforms equipped with smooth ergonomic handrails for secure access to critical areas.

- GrainVue Technology: GrainVue offers cutting-edge monitoring solutions by automating temperature and humidity management. This smart system minimizes the risk of grain spoilage, providing growers with peace of mind and reducing the need for manual monitoring.

What sets GSI apart in the industry is its commitment to quality, breadth of offerings and dealer expertise. “We’re not just selling bins,” explained Tallman. “We’re providing systems that grow with producers over time. Our goal is to deliver solutions that help growers achieve their goals now and in the future.”

GSI’s dealer network plays a key role in this process, offering personalized service to design systems tailored to each farm’s unique requirements. With a focus on safety, quality and long-term value, GSI remains a trusted partner for grain producers across the U.S.

Ready to Build Your Custom Grain Bin System?

Contact your local GSI dealer to learn more about GSI’s grain bins and accessories. Whether you're optimizing an existing setup, expanding your operation or planning a large-scale system, GSI has the customizable solutions you need to succeed.